How sustainable are engineering plastics?

Plastic is the material of choice in many industrial sectors due to its functional properties. But what about sustainability? Can engineering plastics also score over steel or aluminium here? We explore these questions and show what role sustainability plays in plastics extrusion today.

No other material is used as frequently worldwide as plastic. For many technical requirements in the electrical engineering, automotive, chemical and construction industries, there are hardly any economical alternatives to plastic. Among other things, it is valued for its durability - a property that poses a real problem for the environment when it comes to disposable products and packaging. However, thermoplastics, such as those used at Technoform, are not comparable. They are designed to be used for as long as possible and, above all, can be recycled at the end of their service life. This is made possible by modern processes, forward-looking product development that considers the entire product life cycle and the firm conviction that ecological and economic sustainability can be easily reconciled in modern plastic products.

Recycling and downcycling of thermoplastics

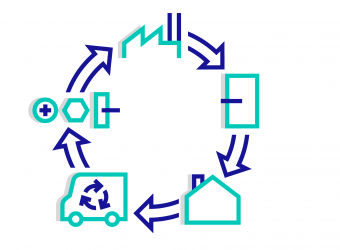

Technoform endeavours to fully recycle plastic products at the end of their life cycle. The aim is to reuse all materials in accordance with the principles of an integrated and consistent circular economy - known as "cradle to cradle" - in order to conserve resources. This is fundamentally possible with thermoplastics: they consist of non-cross-linked chain molecules and can therefore be melted again at higher temperatures. New granulate can thus be obtained from old plastic profiles. This "recyclate" can then be used as a raw material for the manufacture of new products.

However, this process cannot be repeated as often as required: material properties are lost over time during melting and processing. This is because the thermal and mechanical stress changes the structure of the polymer. However, as technical thermoplastics have an extremely long service life, they are superior to other materials in terms of sustainability despite this limitation.

In order for plastic profiles to be recycled, they must be pure materials that can be melted down easily and separated cleanly. If the material is mixed with additives such as adhesives or fire retardants or bonded with other thermoplastics, recycling is not so easy. The recycled material obtained will then have different properties to the original material, which limits the possible applications. This is referred to as "downcycling". Technoform only uses recyclates from its own production cycles in order to always have full control over the composition of the materials used and to ensure the necessary quality.

Circular Economy

The subsequent separation of components and reutilisation of the raw materials used is planned into the design and manufacturing process.

Sustainability starts with product design

Plastic products that are to be recycled must be designed from the outset in such a way that the materials can later be separated by type and returned to the cycle. This places new demands on the development process: it is no longer just a question of fulfilling product specifications, but of reconciling function with sustainability and costs. Technoform sees itself not only as a manufacturer of customised plastic profiles, but also as a consultant that supports its customers with many years of experience and material expertise in product design. This begins with the fundamental question of whether plastic is even suitable as a material for the planned application. If this is not the case, Technoform advises switching to a more suitable material. After all, a plastic profile that fails after a short time has to be replaced - and is therefore anything but sustainable.

Cradle-to-cradle means thinking about products from their end and considering the entire cycle. The success of this approach at Technoform is demonstrated by awards such as the Cradle-to-Cradle® certificate for environmentally intelligent design: Technoform's insulating profiles made of polyamide and low-lambda polyamide received the eco-effectiveness seal in gold - as one of only 84 products worldwide. To achieve the certification, Technoform developed a strategic concept for sorting and upcycling the plastics used. The aim is to manufacture new products from 100% post-consumer plastic. The first steps have already been taken.

Sustainable due to long service life

Sustainability is not just a question of material recycling. How sustainable a product is also determines its service life. This shows that engineering plastics are often more durable and therefore more sustainable than other materials. This is particularly true when they are used in aggressive or oxidising media or come into contact with liquids: A plastic container for chemicals, for example, can withstand the influence of acids significantly longer than comparable containers made of metal. It therefore also needs to be replaced less frequently. In addition to the material properties, the manufacturing process can also be decisive for the long service life: If, for example, a plastic profile requires a very smooth surface or high-precision edges, Technoform uses special tools and processes to ensure that these requirements are met to an above-average degree so that the plastic profile can be used for a very long time.

Extrusion: Profiles without waste

The demand for "zero waste" has also reached the plastics processing industry. In many areas, intensive efforts are being made to reduce waste during production. This is not a challenge for extrusion: it is a very resource-efficient process per se: There is hardly any material waste in the production process, and material consumption for the manufacture of prototypes or production start-up is minimal. In the injection moulding process, on the other hand, significantly more material is lost for sprues.

Dirk Moses, R&D Project Manager, Technoform

Energy efficient processes

The extrusion process is characterised by very low energy requirements. A certain amount of energy is required to melt the material, as well as for the cooling processes. However, this is far less than is required for processing aluminium or steel, for example. Technoform is also working on using energy as efficiently as possible. For example, waste heat from production is utilised for heating and hot water. At the Lohfelden site near Kassel, the heat generated is used to heat around 228 square metres of office space and to heat service water for the sanitary facilities and social rooms.

Outlook: More transparency and alternative raw materials

The recycling of plastics will continue to develop: Better recycling processes will lead to more materials being returned to the material cycle. This also increases the need for transparency in the documentation and labelling of recycled plastics. Ideally, every plastic that is processed somewhere should be given a kind of signature that clearly identifies it and makes it traceable - even if it has been processed or recycled. This is the only way to ensure the quality of recycled materials for all parties involved - retailers, manufacturers and users - and to increase acceptance in the long term.

A lot will also happen in the coming years in the development of plastics made from renewable and biodegradable raw materials. For around 30 years, intensive research has been conducted into plastics that can be disposed of through composting. However, improving biodegradability still means a deterioration in material properties in most cases. In particular, the impact and tensile strength of plastic usually prevents it from being recycled by nature. As a result, biodegradable plastics have not yet been utilised beyond the packaging sector. They are currently not an alternative for plastic profiles in technical applications because they do not achieve the desired thermal or mechanical properties.

Conclusion: sustainability is not a cost factor

Sustainability is already standard in many industries. In plastics processing, however, it often still takes place within the narrow confines of the cost discussion. This shows that it can even be more cost-effective for companies to recycle the materials in their own products as completely as possible. This is gradually leading to a rethink in the planning and budgeting of projects: Reducing waste or returning production residues to the manufacturing process is increasingly being seen as a factor in reducing costs and increasing efficiency. It is recognised that ecological and economic sustainability go hand in hand.

For Technoform, however, sustainability means much more than product recycling. It is about a conscious use of resources in all areas of the company: from energy consumption in production and the development of products with a long service life to reusable packaging systems and regional material procurement to avoiding business trips in cases where video conferencing is possible. For Technoform, sustainability is an attitude: acting in the interests of future generations, focussing on people and developing intelligent innovations.